Inventory

The Inventory module tracks raw materials from receiving through consumption, with full lot traceability and demand forecasting.

Materials

Navigate to Manage → Inventory → Materials to see all raw materials. Each material record includes:

- Name, SKU, and unit of measure

- Buy price (used for BOM cost calculations)

- Minimum and maximum stock levels for reorder alerts

- Allergen flags (auto-aggregated into products via BOMs)

- Nutritional facts per unit (auto-calculated into product nutrition via BOMs)

Lots

Materials are organized into lots for traceability. Each lot tracks:

- Quantity on hand

- Supplier and purchase order reference

- Expiry date

- Receiving date

When consuming materials during production, stock is deducted from lots based on availability.

Stock Movements

Every change to inventory is recorded as a movement with a type:

- Receive — Stock added from a purchase order or manual adjustment

- Consume — Stock deducted during production batch completion

- Adjust — Manual corrections (e.g., spoilage, stocktake differences)

The movement history provides a full audit trail for each material.

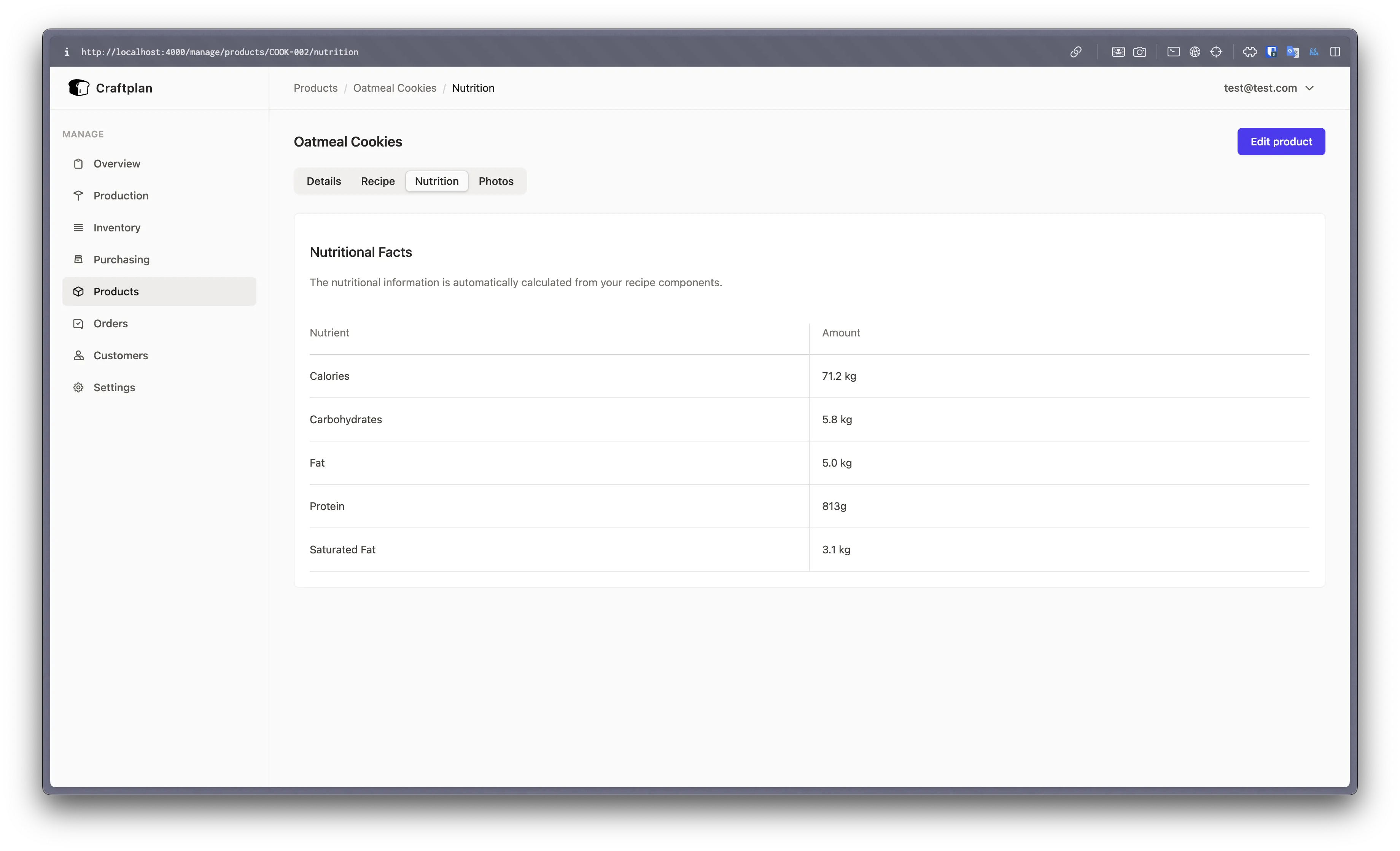

Allergens & Nutritional Facts

- Materials can be tagged with allergens (e.g., gluten, dairy, nuts). These propagate up through BOMs so that products automatically show aggregated allergen information.

- Nutritional facts (calories, protein, fat, carbs, etc.) are defined per material unit. When a BOM references the material, the product’s nutritional facts are calculated from the component quantities.

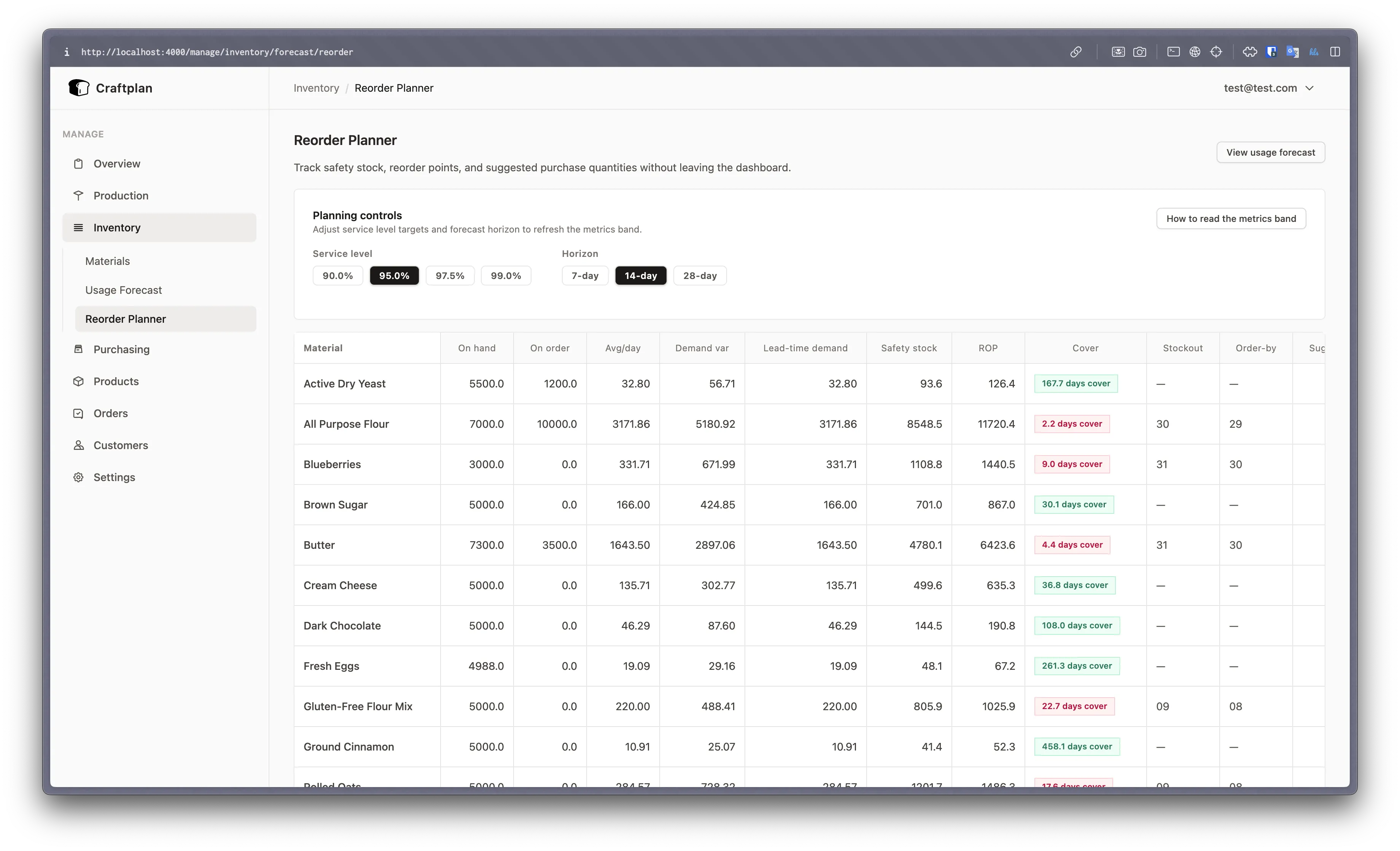

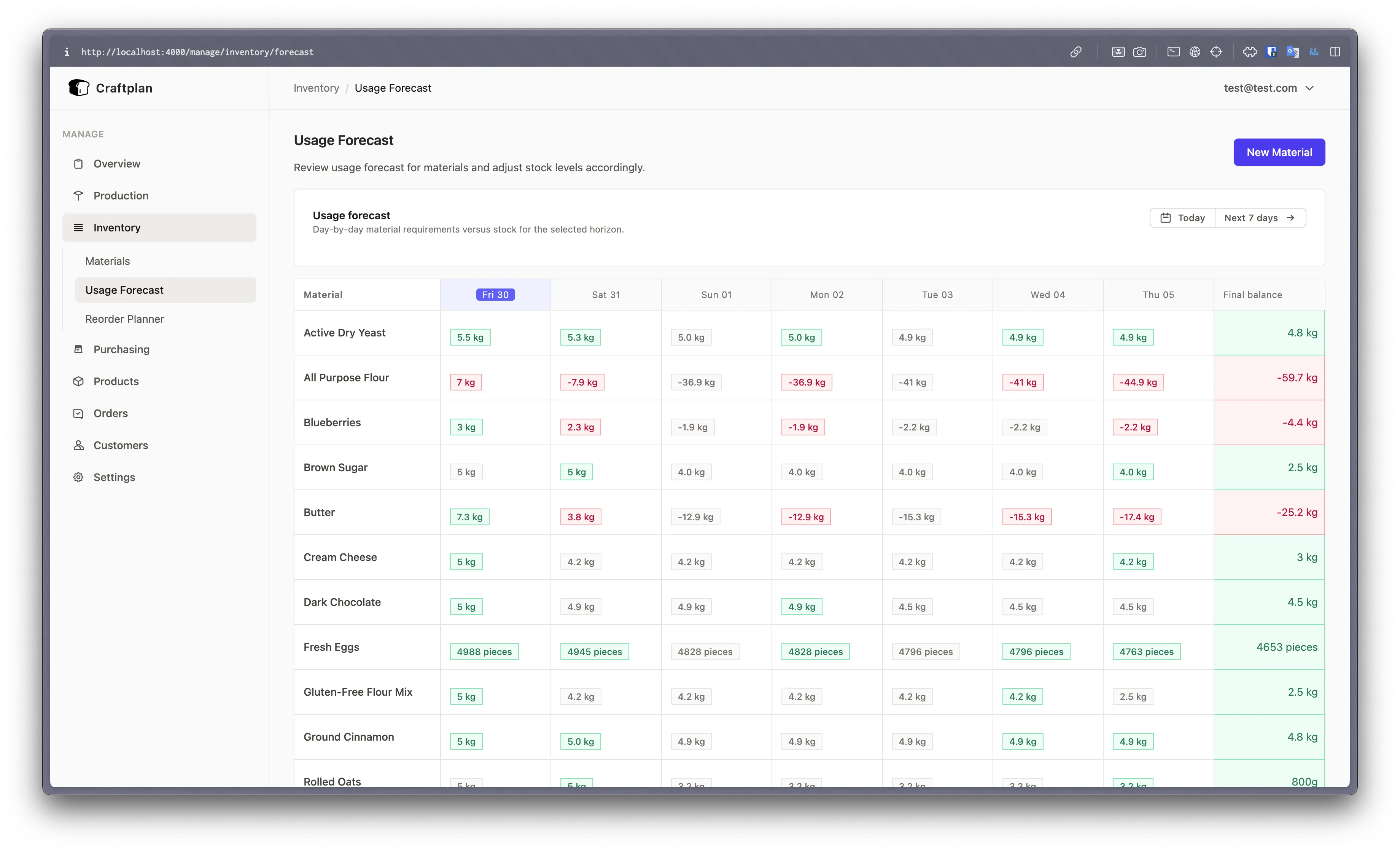

Forecasting & Reorder Planning

The inventory forecasting module (Craftplan.InventoryForecasting) predicts material demand based on upcoming orders:

- Looks at confirmed orders and their delivery dates

- Calculates required material quantities from product BOMs

- Compares demand against current stock levels

- Highlights shortages so you can create purchase orders before running out

The Materials tab on the planner also surfaces shortage warnings for the selected time horizon.